Work with a Membrane Switch Manufacturer Dedicated to Quality

Work with a Membrane Switch Manufacturer Dedicated to Quality

Blog Article

How Membrane Switch Technology Functions and Its Role in Interface Style

Membrane switch innovation is an innovative approach that integrates split materials for touch-sensitive input. When pushed, its layout consists of graphic overlays, conductive layers, and sticky elements that communicate. This communication not just completes an electrical circuit yet additionally influences the overall user experience. Recognizing the ins and outs of this modern technology reveals its substantial effect on user interface layout, prompting questions regarding its applications and future developments in different sectors.

Understanding Membrane Switch Modern Technology

Membrane button technology acts as an essential element in contemporary interface style. This technology incorporates graphic overlays, touch-sensitive membrane layers, and circuit layers to develop a compact, trustworthy input technique for various gadgets. The style commonly consists of several layers, consisting of a published visuals layer that allows individuals to engage with the tool through tactile feedback. Membrane buttons are recognized for their sturdiness, resistance to moisture, and ease of cleaning, making them ideal for settings where conventional mechanical buttons may stop working. Their low-profile layout allows seamless combination right into tools, adding to a streamlined look. Furthermore, Membrane buttons can be tailored with various colors, structures, and icons, enhancing individual experience and visual appeal. This flexibility makes them preferred in consumer electronics, medical devices, and industrial controls, where instinctive interaction is essential. Generally, Membrane switch modern technology represents a significant development in how customers involve with digital user interfaces.

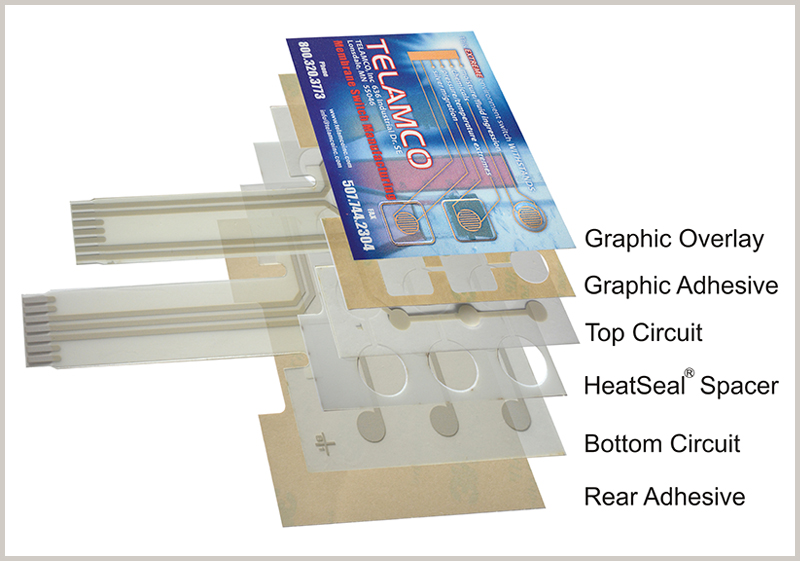

Key Components of Membrane Changes

Membrane changes include several key parts that add to their functionality and design. The conductive layer products, glue and assistance layers, and graphic overlay design each play a crucial function in guaranteeing optimal efficiency and individual communication. Recognizing these elements is important for efficient individual interface style.

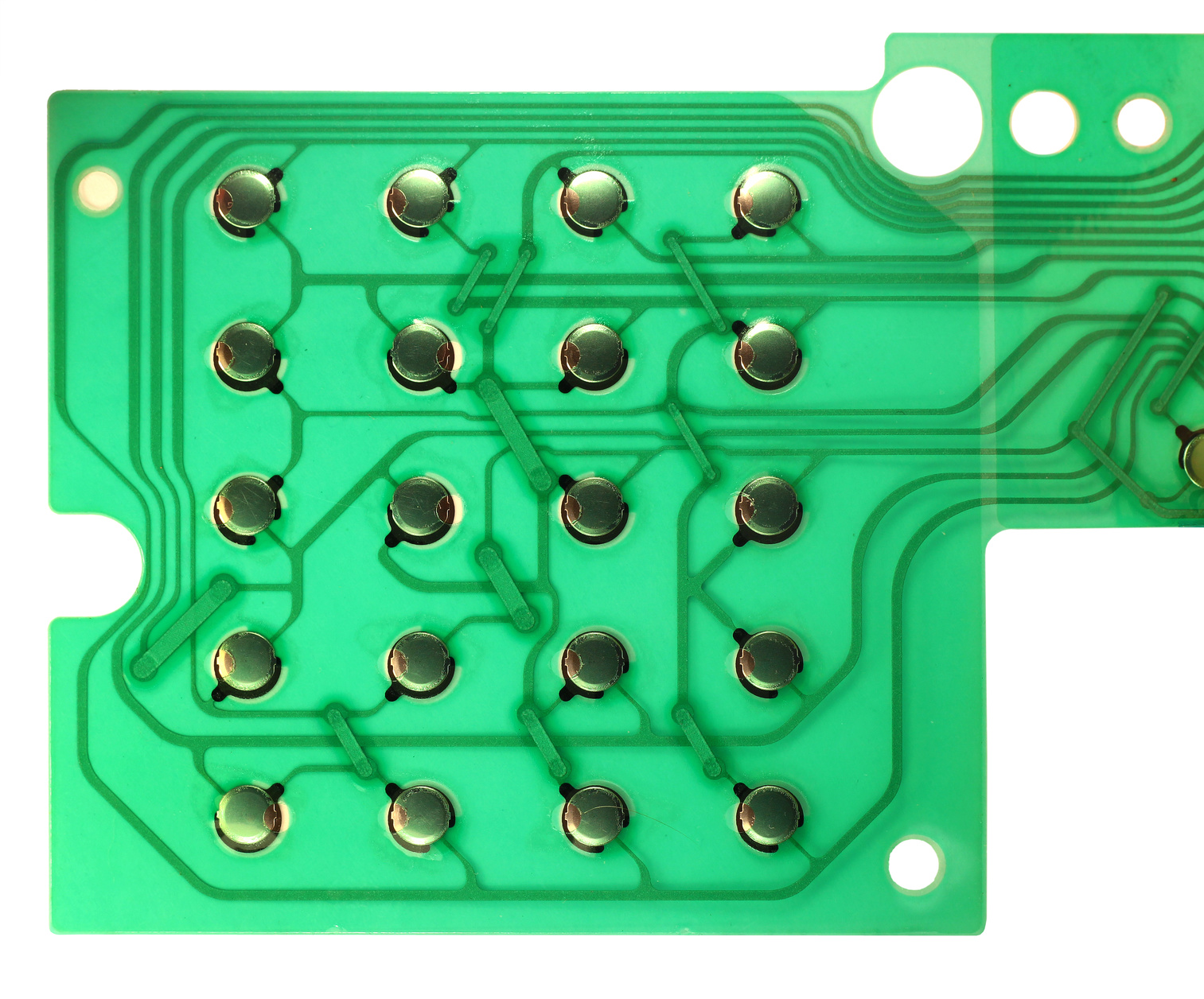

Conductive Layer Materials

Conductive layer products play a crucial function in the functionality and dependability of Membrane buttons. These materials are liable for completing electric circuits when pressure is put on the switch. Usually, a mix of conductive inks, such as silver or carbon, is used to develop these layers. Silver conductive ink is favored for its premium conductivity and toughness, while carbon ink is frequently made use of for affordable applications. The selection of material impacts not just the electrical efficiency but also the total life expectancy of the switch. Furthermore, the thickness and make-up of conductive layers can affect tactile responses and button actuation. Picking the suitable conductive material is crucial for guaranteeing perfect efficiency in varied individual interface applications.

Sticky and Support Layers

Glue and support layers are vital parts that add to the structural integrity and performance of Membrane buttons. These layers supply a robust structure, ensuring that the various aspects of the Membrane switch continue to be safely bound and effectively straightened throughout their operational life. The adhesive layer helps with the accessory of the switch to the underlying surface, using longevity versus ecological factors such as dampness, temperature level variants, and mechanical stress and anxiety. Support layers boost the button's rigidness, protecting against deformation during use and adding to a consistent responsive response. Together, these parts play an essential duty in maintaining the performance and long life of Membrane buttons, inevitably affecting the general individual experience in interface layout.

Graphic Overlay Layout

Although commonly forgotten, visuals overlay style plays an important duty in the capability and looks of Membrane buttons. This style mainly acts as the user interface in between the customer and the electronics, giving both visual appeal and functional clarity. Reliable graphic overlays utilize shade, typography, and symbols to assist customers in steering controls and comprehending device functions. Moreover, the option of materials effects toughness and responsive comments, guaranteeing the overlay holds up against wear while maintaining a positive customer experience. Furthermore, accurate alignment of the overlay with the underlying elements is vital for ideal performance. To conclude, thoughtful visuals overlay design improves usability, adds to brand name identification, and inevitably influences user fulfillment in tools making use of Membrane button innovation.

The Manufacturing Process of Membrane Switches Over

The production procedure of Membrane switches includes several vital steps that guarantee capability and resilience. A graphic overlay is made, including user interface elements and branding. This overlay is printed onto a versatile substratum, generally polyester or polycarbonate, utilizing accuracy printing methods to ascertain clearness and shade accuracy.Next, glue layers are applied, complied with by the integration of conductive traces, typically made from silver or carbon, which are necessary for electric connectivity. These traces are etched or screen-printed onto a different layer. Hereafter, a spacer layer is contributed to develop the needed gap in between the overlay and the circuit layer, permitting responsive feedback when activated.Finally, the elements are assembled and evaluated for quality control, guaranteeing that each Membrane switch fulfills the called for specs for performance and integrity. This meticulous procedure leads to a robust item matched for numerous applications in individual interface style.

Benefits of Utilizing Membrane Switches Over

Membrane switches offer many advantages that make them a recommended option in individual interface design. One considerable advantage is their small and lightweight nature, enabling streamlined designs in numerous applications. In addition, Membrane switches offer a sealed user interface, shielding versus dust, dampness, and pollutants, which enhances longevity and integrity. They are likewise highly adjustable, making it possible for developers to produce unique graphics and layouts customized to particular customer needs.Another advantage is their cost-effectiveness, as they generally require much less material and labor compared to typical switches. The responsive comments of Membrane buttons can be engineered to boost individual experience, providing a gratifying feedback without the mass of mechanical components. Membrane switches can be easily integrated into varied environments, such as clinical devices, industrial equipment, and consumer electronic devices. Overall, these advantages highlight the expanding appeal of Membrane buttons in modern-day individual interface design.

Applications in Various Industries

Widely made use of throughout various industries, Membrane button innovation has actually discovered its place in applications varying from medical gadgets to consumer electronics. In the health care sector, these buttons are essential to tools such as analysis equipment and client tracking systems, offering resilient, easy-to-clean interfaces that stand up to sterilization procedures. The vehicle market uses Membrane buttons in control panels and control panels, offering reputable operation in tough environments.Consumer electronics, including home devices and video gaming consoles, gain from the smooth layout and customizability of Membrane buttons, boosting individual communication. In addition, commercial machinery utilizes these switches for control panels, guaranteeing resistance to dust and dampness while preserving functionality.Moreover, the aerospace and military fields make use of Membrane switches for sturdy applications, where reliability and efficiency are critical. Overall, Membrane switch modern technology offers diverse markets by integrating performance, durability, and aesthetic appeal, making it a flexible option for modern-day customer interfaces.

Creating Interface With Membrane Switches

When creating user interfaces with Membrane buttons, careful consideration of both functionality and aesthetic appeal is important. Membrane changes provide a smooth, inconspicuous layout that can boost visual charm while maintaining functionality. Developers have to concentrate on button design, guaranteeing user-friendly placement for convenience of procedure. The tactile comments given by the Membrane button is important; it can influence individual fulfillment and overall experience.Additionally, color and visuals elements need to straighten with the brand name identity, strengthening acknowledgment and experience. Choosing resilient products that endure wear and tear is additionally essential, as durability adds to functionality with time. Incorporating backlighting can boost visibility in different lights problems, additionally boosting individual communication. Eventually, a well-designed Membrane switch interface balances both kind and function, guaranteeing that the individual experience is both reliable and interesting, satisfying the needs of varied applications across industries.

Future Trends in Membrane Switch Innovation

As Membrane button technology advances, the integration of clever capabilities is becoming progressively famous. These innovations make it possible for improved interactivity and connectivity within individual interfaces (membrane switch manufacturer). In addition, the shift towards environmentally friendly materials mirrors straight from the source an expanding commitment to sustainability in style methods

Smart Membrane Switches

Eco-Friendly Materials Usage

In the middle of the advancements in Membrane button modern technology, a significant pattern is arising towards making use of green materials. Producers are progressively focusing on sustainability by including safe inks and eco-friendly plastics, reducing environmental impact. This shift not only lines up with international ecological criteria but likewise addresses customer need for greener items. Technologies in material science have allowed the advancement of durable, environmentally friendly options that preserve efficiency without jeopardizing high quality. These materials use similar performance to standard choices while lessening waste and toxicity. As markets end up being more eco-conscious, the assimilation of lasting methods in Membrane switch manufacturing is anticipated to climb, strengthening a commitment to environmental responsibility and leading the means for even more lasting interface solutions in the future.

Regularly Asked Concerns

How Do Membrane Changes Differ From Conventional Mechanical Switches?

Membrane switches over differ from traditional mechanical buttons mainly in construction and procedure. They utilize adaptable layers that produce a secured interface, whereas mechanical buttons count on physical movement and get in touch with, resulting in distinctive toughness and tactile responses qualities.

Can Membrane Switches Be Custom-made for Certain Applications?

Membrane switches can without a doubt be customized for details applications - membrane switch manufacturer. Makers make them to fulfill one-of-a-kind needs, enabling for tailored layouts, graphics, and capabilities that boost customer communication and fit certain operational demands effectively

What Is the Lifespan of a Membrane Switch?

The lifespan of a membrane layer button normally ranges from 1 to 5 million actuations, depending upon elements such as worldly quality, ecological conditions, and use regularity. Routine testing can assist determine its longevity and integrity in applications.

Are Membrane Switches Water Resistant or Immune to Chemicals?

Membrane switches can be developed to be water-proof and immune to chemicals, depending on the materials made use of and manufacturing procedures. Appropriate securing and safety layers enhance their resilience in various ecological conditions article and applications.

How Do Membrane Switches Influence Device Power Intake?

Membrane switches can greatly affect device power intake by making certain efficient procedure. Their low power needs during activation assistance lessen power usage, contributing to longer battery life and general enhanced performance in digital tools. Membrane switches are recognized for their durability, resistance to wetness, and ease of cleansing, making them suitable for atmospheres where typical mechanical buttons may fall short. The automotive market utilizes Membrane buttons in dashboards and control panels, supplying dependable operation in challenging environments.Consumer electronics, consisting of home devices and video gaming consoles, benefit from the sleek style and customizability of Membrane switches, boosting individual interaction. In addition, commercial machinery makes use Visit Website of these buttons for control panels, guaranteeing resistance to dirt and wetness while maintaining functionality.Moreover, the aerospace and army markets use Membrane buttons for tough applications, where reliability and efficiency are essential. The development of Membrane button technology is getting in an interesting stage with the introduction of smart Membrane switches, which incorporate sophisticated features and capabilities. Membrane switches over differ from standard mechanical switches mostly in construction and procedure.

Report this page